MORARI

Awarded the Brandenburg 2023 Design Prize in the Young Professionals Product Design/ Industrial Design category and the 1&20 Award of the German Design Council.

Through the participation in this year's theme year of the Kulturland Brandenburg "Baukultur" under the project "Urban Parasites", the focus was especially in the design process on the redesign and revitalization of urban spaces. This was for us, three product design students of the FH;P, the starting point for the conception of Morari (lat. linger) in combination with the examination of the place "stop".

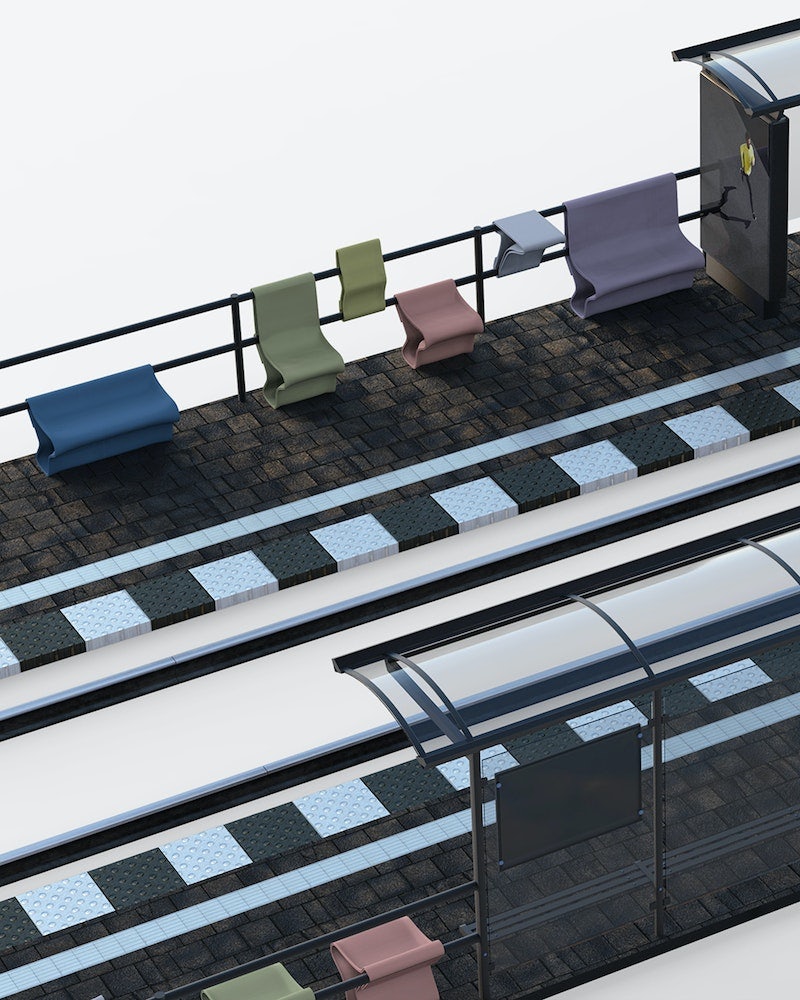

Because bus stops are often inadequately equipped. Despite the existing structures of canopies and seating, the railings are often converted into new seating or leaning facilities.

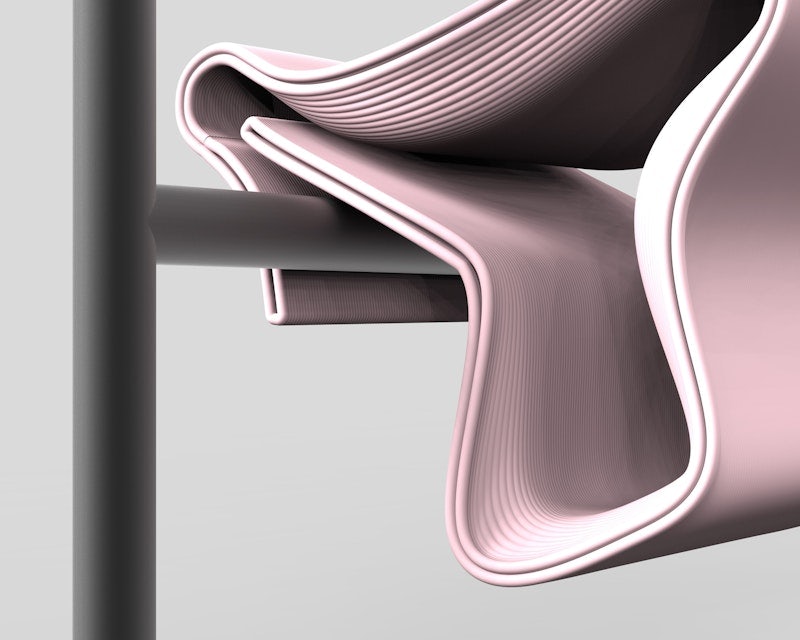

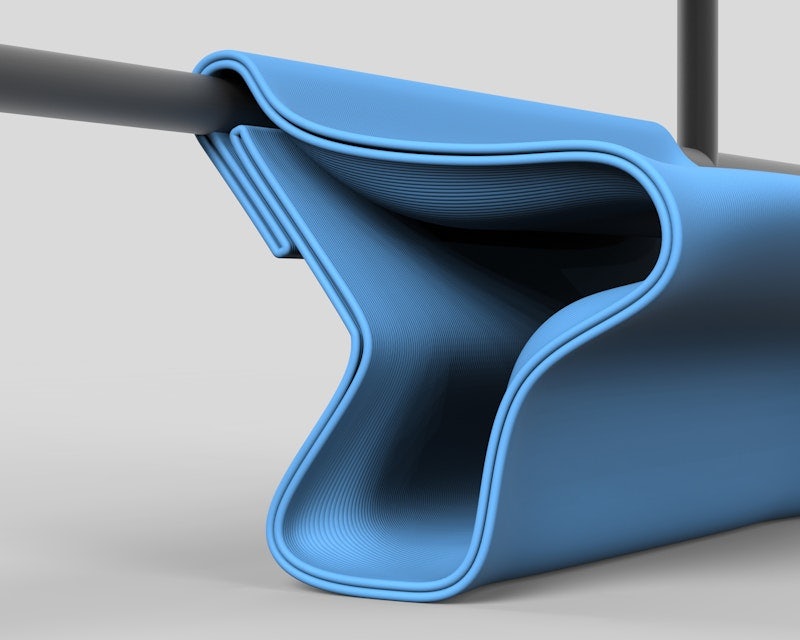

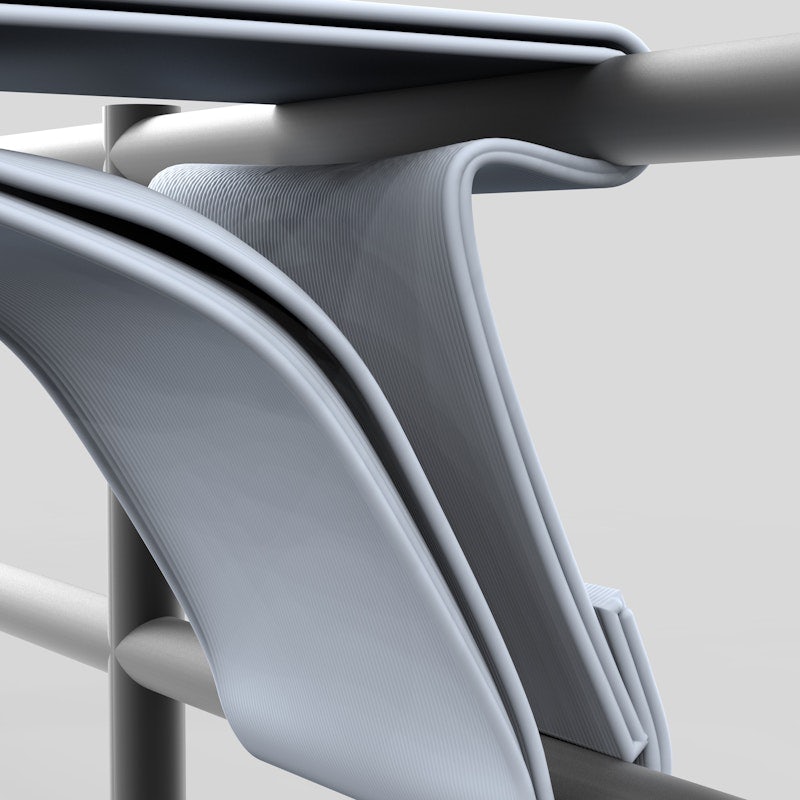

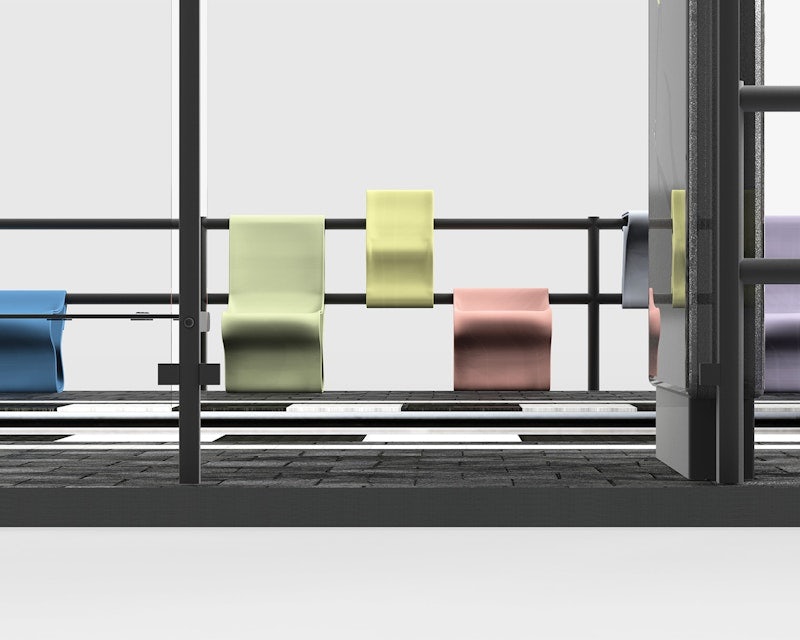

The Morari series starts exactly here and uses the standardized bus stop railings as a pivot and anchor point for the closure system of the furniture.

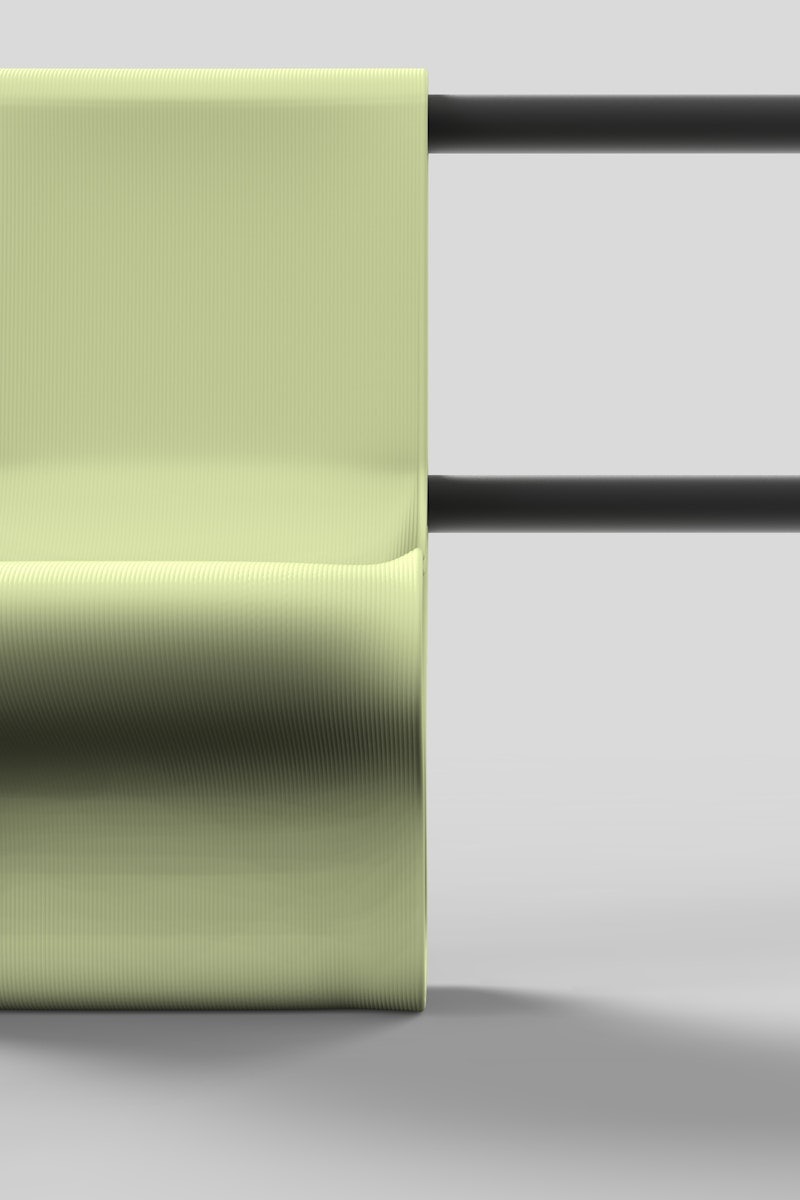

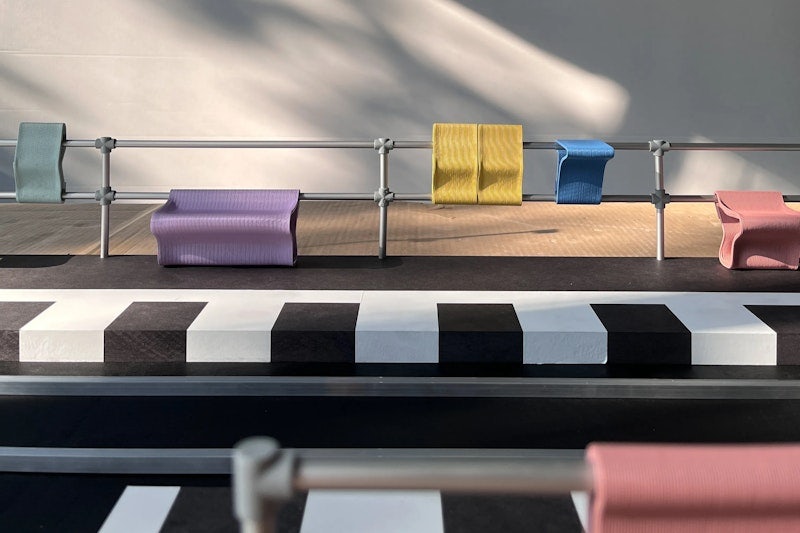

The collection consists of various seating modules, leaning options and tables. Depending on your preference, it is now possible to wait at bus stops in groups or alone, sitting or standing, with or without a lot of luggage.

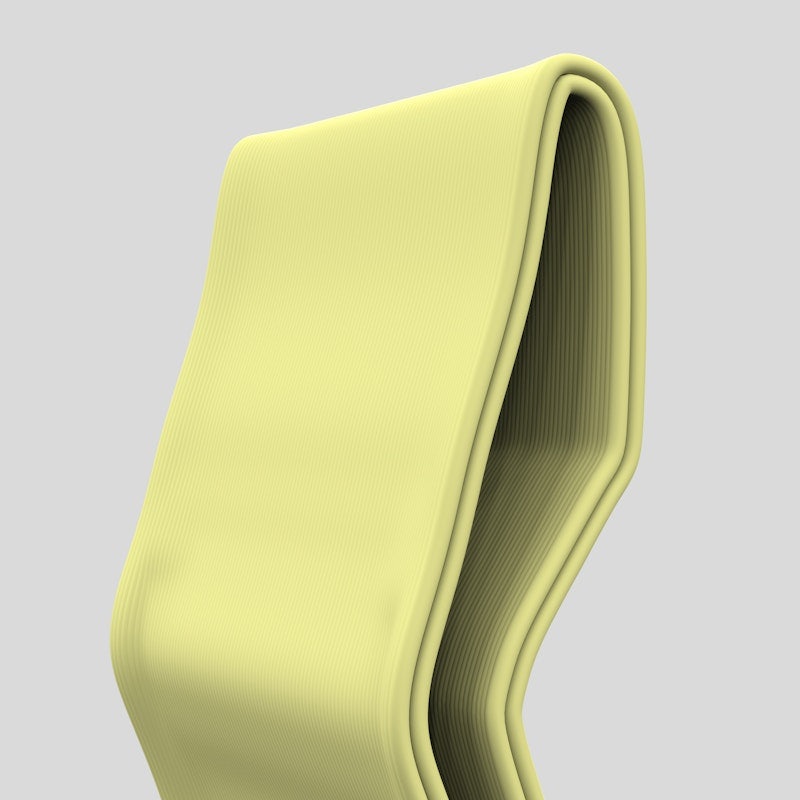

Derived from the manufacturing process in 1-to-1 3D printing by means of a Kuka robot and the use of recyclates, the amorphous design was created, which gives the series an individual character and softens the aesthetics of the stops.

Nowadays, plastic as such usually has a negative connotation. Nevertheless, the choice of material for Morari fell on plastics, more precisely PP (polypropylene), because the material as such impresses in terms of durability, stability and color fastness, hardly any other materials can compete with plastic. However, for the furniture series Morari are used exclusively recycled plastics so-called recyclates, which are thus returned to the cycle, giving the material a longer cycle. Due to the pure white aesthetics of the recyclates, compounds are added in the printing process to give the series the individual color for each individual piece of furniture. Thus, any color choice is possible and also an adaptation to CI colors is conceivable.

For manufacturing, Morari relies on the latest technology through on-demand fabrication using Kuka robots, which are mainly known from the automotive industry. By equipping the eight-axis robot arm with a 3D printing attachment, there are virtually no limits in terms of shape and size. This ensures high flexibility in shaping and manufacturing, as well as material-saving processes compared to conventional methods. Scrap is also kept within limits by the manufacturing process in combination with the choice of material, as the material can be reused one-to-one and reprinted. Morari also relies on local suppliers for production and will soon be producing in Werder (Havel) in cooperation with "Design+Robotics" (Sebastian Voigt).

Details